Ukuqhathaniswa kwezinhlelo zezinto zesekethe ezihlanganisiwe ze-photonic

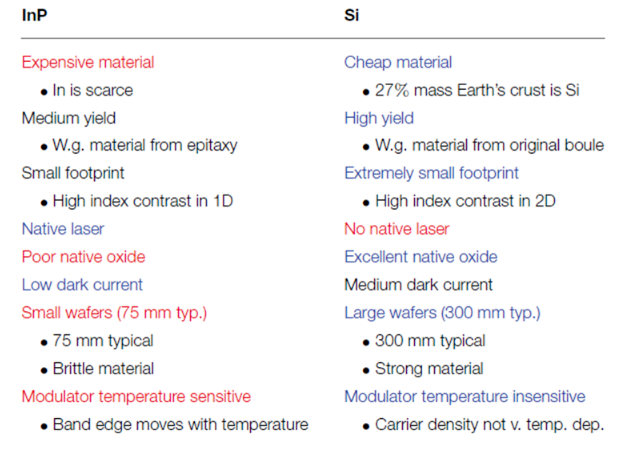

Isithombe 1 sibonisa ukuqhathaniswa kwezinhlelo ezimbili zezinto, i-indium Phosphorus (InP) kanye ne-silicon (Si). Ukungatholakali kwe-indium kwenza i-InP ibe yinto ebiza kakhulu kune-Si. Ngenxa yokuthi izifunda ezisekelwe ku-silicon zihilela ukukhula okuncane kwe-epitaxial, isivuno sezifunda ezisekelwe ku-silicon sivame ukuba phezulu kunesezifunda ze-InP. Ezifunda ezisekelwe ku-silicon, i-germanium (Ge), evame ukusetshenziswa kuphela ku-Isitholi sezithombe(izitholi zokukhanya), kudinga ukukhula kwe-epitaxial, kuyilapho ezinhlelweni ze-InP, ngisho nama-waveguides angasebenzi kumele alungiselelwe ukukhula kwe-epitaxial. Ukukhula kwe-epitaxial kuvame ukuba nobukhulu obukhulu bokukhubazeka kunokukhula kwekristalu elilodwa, njengokuvela ku-ingot yekristalu. Ama-waveguides e-InP anomehluko omkhulu wenkomba yokugqama kuphela ku-transverse, kuyilapho ama-waveguides asekelwe ku-silicon enomehluko omkhulu wenkomba yokugqama kokubili ku-transverse kanye ne-longitudinal, okuvumela amadivayisi asekelwe ku-silicon ukuthi afinyelele ama-radii amancane agobile kanye nezinye izakhiwo ezihlangene kakhulu. I-InGaAsP inegebe lebhendi eliqondile, kuyilapho i-Si ne-Ge zingenalo. Ngenxa yalokho, izinhlelo zezinto ze-InP ziphakeme kakhulu ngokusebenza kahle kwe-laser. Ama-oxide angaphakathi kwezinhlelo ze-InP awazinzile futhi aqinile njenge-oxides angaphakathi e-Si, i-silicon dioxide (SiO2). I-Silicon iyinto enamandla kune-InP, evumela ukusetshenziswa kosayizi abakhulu be-wafer, okungukuthi kusukela ku-300 mm (okuzothuthukiswa maduze kube ngu-450 mm) uma kuqhathaniswa no-75 mm ku-InP. I-InPama-modulatorsngokuvamile kuncike kumphumela we-Stark onqunyelwe yi-quantum, ozwela ekushiseni ngenxa yokunyakaza komphetho webhendi okubangelwa ukushisa. Ngokuphambene nalokho, ukuncika ekushiseni kwama-modulators asekelwe ku-silicon kuncane kakhulu.

Ubuchwepheshe be-silicon photonics ngokuvamile bubhekwa njengobufanele kuphela imikhiqizo engabizi kakhulu, yesikhathi esifushane, enomthamo ophezulu (izingcezu ezingaphezu kwesigidi ngonyaka). Lokhu kungenxa yokuthi kwamukelwa kabanzi ukuthi inani elikhulu lomthamo we-wafer liyadingeka ukuze kusatshalaliswe izindleko zemaski kanye nokuthuthukiswa, nokuthiubuchwepheshe be-silicon photonicsinezinkinga ezinkulu zokusebenza ekusetshenzisweni kwemikhiqizo yesifunda neyesikhathi eside edolobheni. Kodwa-ke, empeleni, okuphambene nalokho kuyiqiniso. Ezisetshenzisweni ezingabizi kakhulu, ezifushane, ezikhiqiza kakhulu, i-laser ekhipha ubuso obuvundlile (i-VCSEL) kanyei-laser eqondisiwe ngqo (I-laser ye-DML): i-laser eguquliwe ngqo ibangela ingcindezi enkulu yokuncintisana, futhi ubuthakathaka bobuchwepheshe be-photonic obusekelwe ku-silicon obungakwazi ukuhlanganisa kalula ama-laser bube yimbi kakhulu. Ngokuphambene nalokho, ezindaweni ezikude, izinhlelo zokusebenza ezikude, ngenxa yokukhetha ukuhlanganisa ubuchwepheshe be-silicon photonics kanye nokucubungula isignali yedijithali (i-DSP) ndawonye (okuvame ukuba sezindaweni zokushisa okuphezulu), kunenzuzo enkulu ukuhlukanisa i-laser. Ngaphezu kwalokho, ubuchwepheshe bokuthola obuhambisanayo bungenza ukushiyeka kobuchwepheshe be-silicon photonics ngezinga elikhulu, njengenkinga yokuthi ugesi omnyama mncane kakhulu kunogesi we-oscillator wendawo. Ngesikhathi esifanayo, kuyiphutha futhi ukucabanga ukuthi kudingeka inani elikhulu lomthamo we-wafer ukuze kuhlangatshezwane nezindleko zemaski kanye nokuthuthukiswa, ngoba ubuchwepheshe be-silicon photonics busebenzisa osayizi bama-node abakhulu kakhulu kune-complementary metal oxide semiconductors (i-CMOS) ethuthukisiwe kakhulu, ngakho-ke ama-masks adingekayo kanye nokugijima kokukhiqiza kushibhile kakhulu.

Isikhathi sokuthunyelwe: Agasti-02-2024